- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

You use a steel file to shape, smooth, or finish metal, wood, and plastic. Steel files stand out as essential tools in any workshop. Choosing the right hand files helps you work faster and achieve cleaner results. Different types allow you to handle unique tasks. Regular maintenance keeps your steel files sharp and effective. When you master hand files, you gain more control over your projects.

Tip: Pick the correct steel file for each job to avoid damaging your work or tools.

Pick the correct steel file for each task. This helps you work faster and makes your work look better.

Each file has its own shape and job. Flat files smooth things. Round files work in curved spots.

Use the right way to file and follow safety rules. This keeps you safe and your files sharp.

Clean your steel files and put them away the right way. This stops rust and helps them last longer.

Look at your files often. Get new ones if they are dull or broken. This helps you do your best work.

You use a steel file to shape, smooth, or finish materials like metal, wood, or plastic. Steel files belong to the family of hand files. They have rows of sharp teeth that cut away small amounts of material. You can find many types of hand files, each designed for a specific job. Some work best for rough shaping, while others help you achieve a fine, smooth finish. When you pick the right file, you make your work easier and more precise.

Note: Steel files are harder than most other workshop tools. This extra hardness helps them keep their sharp teeth and cut effectively, but it also makes them more brittle if dropped.

Steel files have a simple but strong design. Each file has two main parts: the tang and the blade. The tang is the narrow end that fits into a handle. The blade is the working part covered in teeth.

Here is how manufacturers make steel files:

They start with high-carbon steel rods. This material gives the file its hardness and long life.

They forge the rods into the shape of the file.

Machines cut the teeth into the blade. The pattern depends on the file’s use.

The file goes through heat treatment. This step hardens the steel and makes the teeth sharp.

Tempering follows. It reduces brittleness and balances toughness.

Some files get a coating of diamond particles for extra cutting power.

Each file passes a careful inspection to check for uniform teeth and defects.

Part | Material | Purpose |

|---|---|---|

Tang | High-carbon steel | Attaches to handle |

Blade | High-carbon steel or diamond-coated | Cutting and shaping |

You will notice that hand files made from high-carbon steel stay sharp after many uses. Diamond-coated files work even better for tough jobs. Both types of steel files help you get clean, accurate results in your workshop.

When you work in a workshop, you should know about different hand files. Each one has its own shape and job. If you learn about these types, you can pick the best tool for your project.

Flat files are the most common kind. They have a rectangle shape and flat sides. You use them to shape, smooth, and finish flat things.

Flat files come in single-cut and double-cut styles.

Single-cut files have teeth going one way. They make things smooth.

Double-cut files have teeth crossing each other. They take off more material fast.

Tip: Use flat files to sharpen tools, smooth edges, and take off burrs from metal or wood.

Typical uses for flat files:

Shaping and smoothing flat things

Taking off sharp edges

Metalwork and woodworking

Sharpening tools

Removing rust or paint

A half round file has one flat side and one curved side. This makes it useful for many jobs. The flat side works on straight things. The curved side works on round things.

The half round file is good for cleaning, shaping, and taking off sharp edges on both curved and flat places.

It helps finish corners and clean welded joints in metal.

In woodworking, it shapes curved edges and smooths inside bowls or handles.

Note: Plumbers and pipe fitters like the half round file. It helps them clean pipe ends and make sure pipes fit well.

You see the half round file in many workshops because it works on both flat and curved things.

Round files are also called rat-tail files. They are round and get smaller at the end. You use them to make holes bigger, smooth curved openings, and shape round grooves.

The teeth cover the whole file, so you can use them in small spaces like jump rings or tiny holes.

Round files are great for jewelry, metalwork, and woodworking when you need to smooth inside curves.

Tip: Use round files for careful work on soft metals like silver and copper. Do not use them on hard steel or they might get damaged.

Square files have a square shape. You use them to make square holes bigger, file slots, and fix corners.

They help you make sharp angles and clean up grooves or keyways.

Square files are good for both metal and wood.

You can use square files to mark lines for bending or finish inside corners where other files cannot go.

Triangular files are also called three-square files. They have three sides that make a triangle.

You use them to file angles, clean corners, and sharpen saw teeth.

They fit into small spaces and help you make neat grooves or notches.

Note: Triangular files are important for jewelers. They use them to get prongs ready and mark lines for bending.

A crossing file looks like a half round file but has two curved sides with different curves.

The pointy, thin end lets you reach small spots and work on curved places.

Both sides have a double curve, which helps you make and finish many curved shapes.

Key features of a crossing file:

Thin end for small spaces

Two curved sides for tricky curves

Double cut teeth for fast work

Good for cleaning inside rings, holes, and curved places

Tip: Use a crossing file to finish frames, cutouts, or any spot with hard curves.

A barrette file has a flat side with teeth and a slanted, smooth back.

The shape gets thinner at the end, so you have more control.

You use a barrette file for careful finishing, cleaning gear teeth, and working in tight slots.

Note: Barrette files are popular for watchmaking, fixing jewelry, and other careful jobs. They let you take off material without hurting nearby areas.

Needle files are small and thin. They come in many shapes like flat, half round, barrette, round, square, triangle, and knife.

You use needle files for careful shaping, smoothing, and fixing small metal parts.

They are great for jewelry, electronics, and watches.

Common uses for needle files:

Shaping and smoothing edges

Filing bezel wire for stone settings

Taking off small flaws

Finishing rings, pendants, and tiny parts

Tip: Needle files come in different roughness. Pick coarse ones for heavy work or fine ones for gentle smoothing.

Rasp-cut files, or rasps, have big, rough teeth.

They take off wood fast and do not clog easily.

Rasps are best for wood jobs like shaping, carving, and making joints.

How rasp-cut files are different from regular files:

Rasps cut wood quickly and leave it rough.

Regular files have teeth in rows and are better for smoothing.

Even rough regular files cannot take off wood as fast as rasps.

Note: Use rasps for rough shaping. Switch to regular files to make things smoother.

Knife sharpening files are thin and get smaller at the end.

You use them to sharpen knives, scissors, and other cutting tools.

The thin edge fits in small spaces and sharpens fine edges.

Knife sharpening files usually have single-cut teeth for a smooth, sharp finish. You can use them on metal blades, garden tools, and some woodworking tools.

Table: Quick Guide to Types of Hand Files

File Type | Shape/Feature | Typical Use |

|---|---|---|

Flat File | Rectangular, flat sides | General shaping, smoothing, tool sharpening |

Half Round File | Flat + rounded side | Curved/flat surfaces, deburring, cleaning |

Round File | Circular, tapered | Enlarging holes, curved grooves |

Square File | Square cross-section | Filing corners, slots, keyways |

Triangular File | Three sides, triangle shape | Angles, grooves, saw teeth |

Crossing File | Double curved, tapered end | Compound curves, deburring, frames |

Barrette File | Flat, beveled safe back | Fine finishing, precision work |

Needle File | Small, various shapes | Detail work, jewelry, electronics |

Rasp-Cut File | Coarse, raised teeth | Wood shaping, carving |

Knife Sharpening File | Thin, tapered | Sharpening blades, fine edges |

Remember: If you know the types of hand files, you can pick the right one. You will get better results and keep your steel files safe.

Steel files help you shape and smooth many things in your workshop. You can use them to take away rough spots and make edges smooth. They also help you make surfaces flat or curved. There are many types of files, and each one has a special job.

Flat files are good for big, flat metal pieces. You can use them to smooth out curves and fix edges.

Half-round files work well on curved places, like inside rings or handles. They also help clean up curved edges and remove fire scale.

Crossing files are made for tight spots and big curved areas. Their shape fits many different curves.

Barrette files give you control for careful shaping. You can use them without hurting the metal around your work.

Needle files are best for tiny, detailed jobs. They help you finish and shape small parts.

Tip: Machinists use these files to make metal parts fit just right. You can use them for rough work or for making things very smooth.

Steel files are important for cleaning and taking off sharp bits. When you cut or drill metal, sharp edges and burrs can show up. You need to get rid of these for safety and a nice finish. Steel files let you work on tricky shapes and give you good control.

File Type | Shape/Design | Deburring & Cleaning Use Cases | Effectiveness Highlights |

|---|---|---|---|

Flat File | Flat on both sides | Deburring edges of large flat metal areas | Quick smoothing and sharpening, versatile for flat surfaces |

Half-Round File | One side rounded, one flat | Deburring convex surfaces, hollow shanks, welded joints | Good for curved surfaces and corners, versatile |

Tapered File | Tapered end, double cut pattern | Deburring inside shanks, holes, curved surfaces | Efficient and uniform material removal |

Barrette File | Triangular, tapered thickness/width | Wider surfaces, narrow edges, outside curves | Leaves flat, smooth upper surface, protects adjacent areas |

Round File | Rounded, tapered point | Cleaning rounded holes, circular openings, concave surfaces | Fast material removal, good access |

Steel files give you more control than power tools. This helps you finish hard shapes and not make mistakes. Power tools work fast, but they do not give you the same feel. Steel files last a long time and you can use them again and again.

You can use steel files on lots of materials, but some work better than others. Metal working files are made for metals like carbon steel, stainless steel, and cast iron. They also work on softer metals like aluminum, brass, and copper. You can use them on some plastics, but you have to be careful.

Material Type | Compatibility with Steel Files | Limitations and Recommendations |

|---|---|---|

Carbon Steel | Highly compatible | Use coarse files for fast removal. |

Stainless Steel | Compatible | Use fine-cut files to reduce heat. Lubricate to prevent damage. |

Hardened Steel | Compatible | Use durable files. Fine flutes last longer. |

Cast Iron | Compatible | Use tough files. Cast iron is abrasive. |

Non-Ferrous Metals | Compatible | Use open flute files to prevent clogging. |

Certain Plastics | Compatible | Use gentle cuts. Avoid melting or distortion. |

Low-Density Plastics | Not recommended | Files clog easily. |

Soft Elastomers | Not suitable | Uneven wear and poor cutting. |

Glass and Ceramics | Not compatible | Risk of chipping and tool damage. |

Note: Always clean your files after using them on soft metals or plastics. This keeps them sharp and ready for next time.

Metal working files are used in many workshops. You use them to shape, smooth, and finish metal parts. Machinist files come in many shapes and sizes. Each one is made for a special job.

Machinist files help you fit parts together. You can use them to take off burrs, smooth welds, and fix edges.

Metal working files work for big and small projects. You can use them for making tools, fixing things, and custom jobs.

You get better results when you pick the right file. Flat files are good for big areas. Needle files help with small, careful work.

Machinists trust these files for accuracy. You can use them to make sure parts fit just right.

Tip: Keep your metal working files clean and sharp. This helps you get the best finish and makes your work easier.

Steel files are still a great choice for shaping, smoothing, and finishing. You can use them on many things, and they give you control that power tools do not. When you know what each file does, you get better results and keep your tools working well.

You get the best results from steel files when you use the right technique. Hold the file handle firmly in one hand. Place your other hand on the tip for control. Push the file forward across the workpiece. Lift it on the return stroke. This keeps the teeth sharp.

Different files work best for different jobs. The table below shows how each type affects your finish:

File Type | Recommended Use | Effect on Finish |

|---|---|---|

Large files | Remove more material | Rougher finish |

Small files | Remove less material | Smoother finish |

Flat files | General purpose work | Overall smoothing |

Square files | Rectangular holes | Precise shaping |

Round files | Round holes | Smooth curved edges |

Triangular files | Acute angles | Detail on sharp angles |

Half-round files | Curved faces of grooves | Fine smoothing on curves |

Keep your file clean and lightly oiled. This helps you get a smoother finish and makes your file last longer.

Tip: Use steady, even strokes. Do not rush. Let the file do the work.

You protect yourself and your tools when you follow safety rules. Always clamp your workpiece tightly. This stops it from moving or vibrating. Wear safety glasses to shield your eyes from metal or wood shavings. Use a handle on the tang of the file. This prevents hand injuries.

Check your file for cracks or damage before you start.

Keep your workspace clean and free of clutter.

Store files away from moisture to prevent rust.

Note: Never use a file without a handle. The tang can hurt your hand if it slips.

Many beginners make the same errors when using steel files. Watch out for these:

Using a file on material harder than the file. This ruins the file quickly.

Not cleaning the file. Metal pins clog the teeth and reduce cutting power.

Forgetting to lubricate the file. This causes friction, clogging, and rust.

Failing to clamp the workpiece. It vibrates and gives a poor finish.

Applying pressure on the return stroke. This dulls the file fast.

Remember: Clean, lubricate, and use the right technique. Your files will last longer and your work will look better.

If you take care of your steel files, they stay sharp. Good care helps you save money and finish jobs faster. You can stop your tools from breaking and get better results if you follow the right steps.

Steel files pick up dirt and metal bits when you use them. Cleaning them often is very important. There are different ways to clean your files, and each way works in its own way.

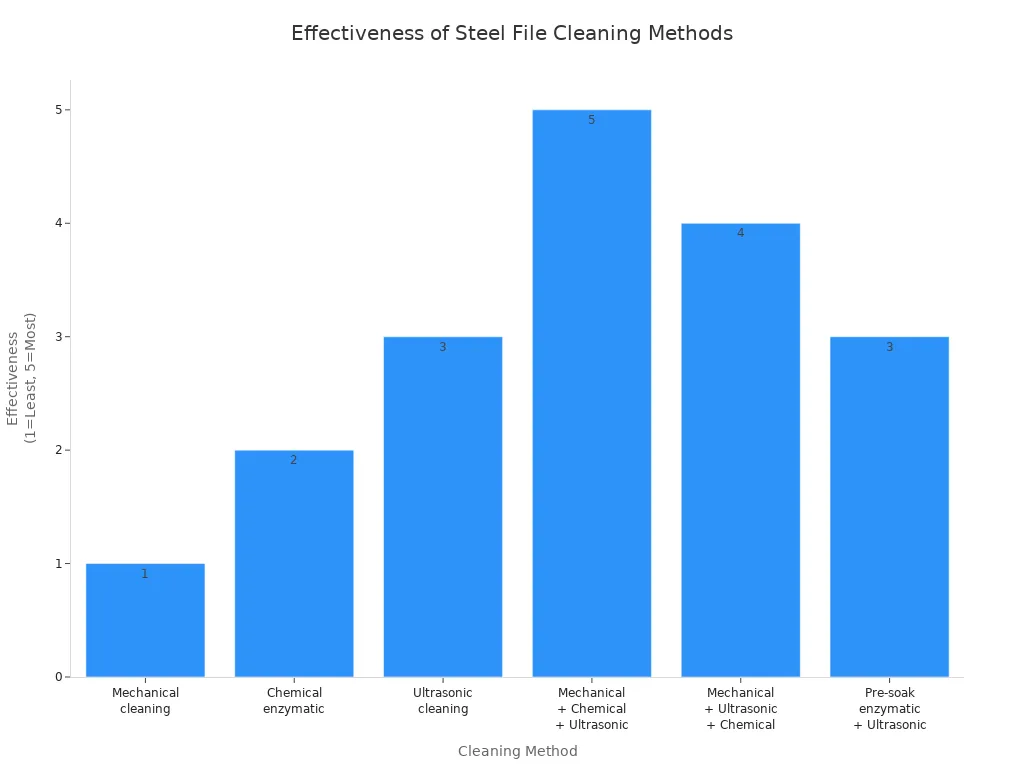

Cleaning Method(s) | Description | Effectiveness at Removing Debris |

|---|---|---|

Mechanical cleaning | Use a scouring sponge soaked in chlorhexidine 0.2%, applied with rotational movement on files | Removes debris but less effective alone, especially in file shafts and smaller sizes (15, 25) |

Chemical cleaning (enzymatic) | Immersion in Micro 10 enzyme solution (1/133 dilution) for 15 minutes | Improves debris removal compared to mechanical alone; enzymatic action helps break down debris |

Ultrasonic cleaning | Ultrasonic bath for 5-15 minutes | More effective than mechanical or chemical alone; significantly reduces debris, especially when combined |

Combination: Mechanical + Chemical + Ultrasonic | Files cleaned mechanically, then treated with Micro 10 enzyme both conventionally and ultrasonically for 15 min each | Most effective method; significantly reduces debris in file heads and shafts; superior to other groups |

Combination: Mechanical + Ultrasonic + Chemical | Mechanical cleaning plus ultrasonic Micro 10 enzyme treatment only for 15 min | Effective but less so than above; higher debris remains especially in shafts |

Pre-soaking in enzymatic cleaner before ultrasonic cleaning | Files soaked in enzymatic cleaner prior to ultrasonic cleaning | No additional benefit observed compared to ultrasonic cleaning alone |

Tip: Use a file card or wire brush to clean your file after each use. For deep cleaning, try an ultrasonic bath and enzyme cleaner.

Storing your steel files the right way keeps them safe. You want to keep them dry so they do not rust.

Put files in closed boxes or tool chests, not on open shelves.

Wrap files in VCI paper or spray them with anti-rust spray.

Add silica gel packs to storage boxes to soak up water.

Sort files by size or type so they do not scratch each other.

Wipe a little oil on your files before storing, especially if it is humid.

Check your files often for rust or damage.

Keep files away from chemicals and sunlight.

Note: Cloth or leather rolls are good for carrying files, but they do not stop rust if you store files for a long time.

You should check your files often to make sure they work well. File care means knowing when to sharpen or get a new one.

Most steel files can be sharpened 10 to 20 times.

Some people get a new file after sharpening once for best results.

If your file does not cut or looks shiny, you need a new one.

Switch between files while working to help them last longer.

Clean your files after every use to keep them sharp.

Soak files in vinegar overnight to help remove stuck dirt.

Get a new file if it does not make metal dust or feels dull.

Taking care of your files keeps them sharp and ready. Good care means you do not have to stop working to fix or buy new tools. When you look after your files, your workshop runs better and safer.

You gain better results when you know your steel files. Picking the right file for each job helps you shape metal faster and avoid mistakes. Good maintenance keeps your tools sharp and ready. You save time and improve your work. Try these habits:

Clean and organize your files often.

Remove old tools when you add new ones.

Label storage for easy access.

Explore guides for more tips on file selection and care. Share your own maintenance ideas or review your file collection today!

You should use a file card or a wire brush. Move it across the teeth to remove debris. For deep cleaning, soak the file in an enzyme solution and use an ultrasonic cleaner. This keeps your file sharp and ready for use.

Check if your file feels dull or slides over the material without cutting. If you see shiny spots or it does not make metal dust, it is time to get a new one.

No, you should match the file to the material. Use coarse files for wood and fine files for metal. Files for plastic need gentle strokes. Using the wrong file can damage both the tool and your project.

Material | File Type | Best Practice |

|---|---|---|

Metal | Fine-cut | Light, even strokes |

Wood | Rasp-cut | Firm, steady strokes |

Plastic | Fine or smooth | Gentle pressure |

Files rust when they get wet or stay in humid places. You can prevent rust by wiping your files with oil, storing them in dry boxes, and using silica gel packs. Always dry your files after cleaning.

Tip: Store files in a closed box to keep moisture away.

Home | Products | About KENDO | Distribution Network | Events | Contact Us