- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

You may know circlip pliers by other names like snap ring pliers, retaining ring pliers, or C-clip pliers. These tools help you install and remove circlips. Circlip pliers types include internal circlip pliers and external circlip pliers. Each type works best for certain jobs. If you use the wrong one, you might damage parts. Many people wonder what are circlips and why they matter. They hold parts in place on shafts or inside bores. You will find many circlip pliers types, each designed for different types of circlips. When you understand what are circlips, you can see why using the right tool matters.

Tip: Always match the circlip pliers types to your task for better results.

Use the right circlip pliers type—internal for inside bores and external for around shafts—to avoid damage and work efficiently.

Choose the correct size and tip style (straight, bent, or long-nose) to reach tight spaces and handle circlips safely.

Circlip pliers save time, protect parts, and reduce injury risks compared to regular pliers.

Maintain your circlip pliers by cleaning, lubricating, and inspecting them regularly to keep them reliable and long-lasting.

Always wear safety glasses and use proper techniques to prevent accidents and ensure smooth repairs.

You may wonder, what are circlips? Circlips are small, circular fasteners that fit into grooves on shafts or inside bores. They hold parts in place and prevent movement. You often see them called snap rings. When you ask, what are circlips used for, think about machines, cars, or even electronics. These rings keep gears, bearings, or wheels from sliding off.

Circlip pliers help you handle these rings. You use circlip pliers to install or remove snap rings quickly and safely. These tools have special tips that fit into the holes on the ends of circlips. You squeeze the handles, and the tips either open or close the ring. This action lets you place or remove the ring without bending or breaking it.

There are two main types of circlip pliers:

Internal circlip pliers: You use these for circlips inside a bore.

External circlip pliers: You use these for circlips on a shaft.

Note: Using the right circlip pliers for each job keeps your parts safe and makes your work easier.

You need circlip pliers because regular pliers cannot handle snap rings well. Circlip pliers grip the rings securely and prevent slipping. If you try to use the wrong tool, you might damage the ring or the part it holds.

Here are some reasons to use circlip pliers:

They save time during repairs.

They reduce the risk of injury.

They protect the types of circlips from damage.

They work for both internal and external snap rings.

They help you reach tight spaces.

Circlip Pliers Benefit | How It Helps You |

|---|---|

Secure Grip | Prevents slipping |

Right Fit | Matches ring size |

Special Tips | Fits ring holes easily |

You will find circlip pliers in toolboxes for car repair, electronics, and home projects. When you use the correct tool, you get better results and keep your equipment in good shape.

Understanding the different types of circlip pliers helps you choose the right tool for every job. Each type has a unique design and function. Using the correct circlip pliers types prevents damage and improves your efficiency.

Internal circlip pliers help you install or remove circlips inside a bore or housing. When you squeeze the handles, the tips compress the circlip, making it smaller. This action lets you fit the ring into a groove inside a hole. You need these pliers when working on gearboxes, pumps, or any assembly where the circlip sits inside a cavity.

Industry standards define the performance of internal circlip pliers. You can see the main specifications in the table below:

Specification Aspect | Details/Values |

|---|---|

Applicable Standard | DIN 5256 |

Material | High-performance alloy steel |

Jaw Shape | Straight jaws, forged tips |

Handle Coating | PVC coated handles |

Finish | Phosphate finish, anti-corrosion treated |

Additional Features | Stainless steel ring for ergonomics and safety |

Size Ranges (mm) | 12-25, 19-60 |

Length (mm) | 150, 180 |

Weight (g) | 100, 166 |

You often find internal circlip pliers in a circlip plier set. These sets give you multiple sizes for different jobs. The chart below shows how length and weight relate for internal circlip pliers:

Tip: Always check the size range before you start. Using the wrong size can damage the circlip or the bore.

External circlip pliers work on circlips that fit around a shaft. When you squeeze the handles, the tips expand the circlip, making it larger. This lets you slip the ring over the end of a shaft and into its groove. You use external circlip pliers for axles, spindles, or any part where the circlip sits outside a component.

The table below lists the main specifications for external circlip pliers:

Specification Aspect | Details/Values |

|---|---|

Applicable Standard | DIN 5254 |

Material | High performance alloy steel |

Hardness | 45-50 HRC |

Jaw Shape | 90° offset jaws, forged tips |

Handle Coating | PVC coated handles |

Finish | Black finish, anti-corrosion treated |

Size Ranges (mm) | 8-13, 12-25, 19-60, 40-100, 85-165 |

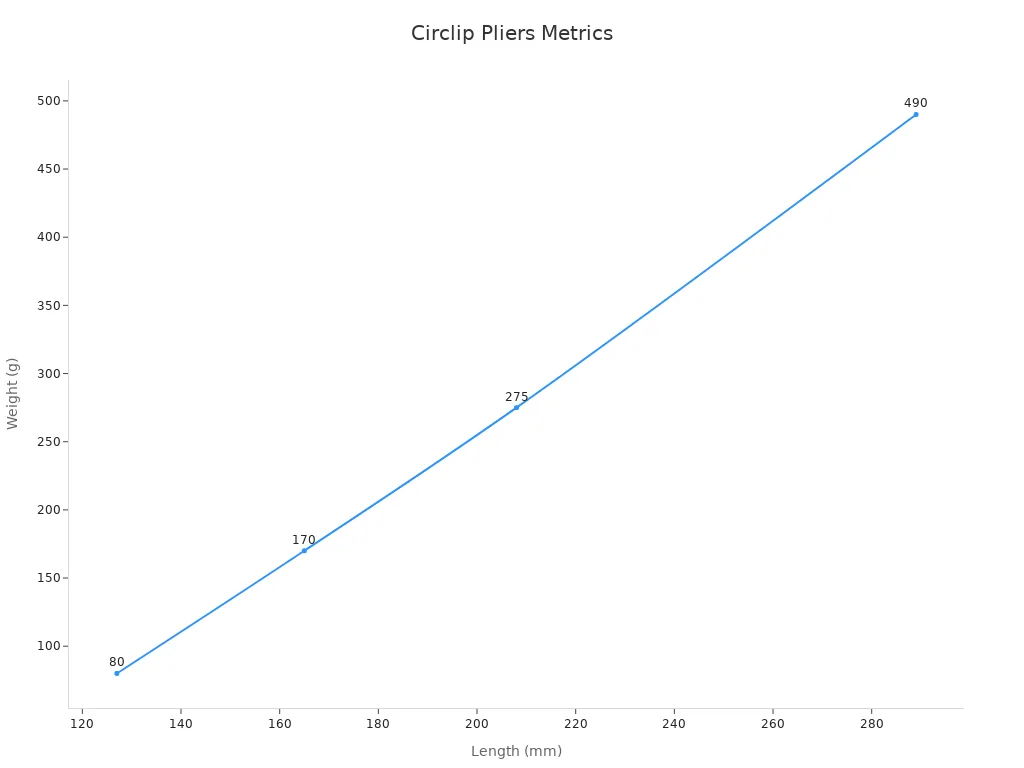

Length (mm) | 127, 165, 208, 289 |

Weight (g) | 80, 170, 275, 490 |

You often find external circlip pliers in a circlip plier set. These sets help you handle different shaft sizes. Using the correct external circlip pliers keeps the ring from stretching or breaking.

Note: Internal and external circlip pliers look similar, but they work in opposite ways. Internal types compress, while external types expand the circlip.

Adjustable circlip pliers give you flexibility. You can change the jaw width to fit different circlip sizes. Some models let you switch between internal and external functions. These reversible pliers save space in your toolbox. You only need one tool for both jobs.

A circlip plier set often includes adjustable circlip pliers. This design works well for repair shops or anyone who handles many circlip pliers types. Rack-type circlip pliers also fall into this group. They use a rack mechanism for smooth, precise movement.

Tip: Adjustable and reversible pliers help you work faster. You do not need to switch tools for each task.

Tip style matters when you work in tight or awkward spaces. The three main tip styles are straight, bent, and long-nose.

Straight tips: Good for open, easy-to-reach areas. They give you direct access to the circlip.

Bent tips (angled tip circlip pliers): Useful for hard-to-reach spots. The angle helps you reach around obstacles.

Long-nose tips: Best for deep or narrow spaces. The long shape lets you reach circlips buried inside assemblies.

Round-nose pliers have conical jaws for precise gripping. Long-nose pliers reach deep areas. Bent or angled tip circlip pliers help you access difficult angles. You often find these in electronics or jewelry work. Fixed-tip circlip pliers offer extra stability for delicate jobs.

Callout: Choosing the right tip style makes your work easier and safer. It also prevents damage to the circlip or the part.

Heavy duty circlip pliers handle tough jobs. You need them for industrial settings where you face high loads or frequent use. These pliers use high carbon steel for strength. They often have bent handles for better grip and control. Some models come with four replaceable heads, making them multifunctional.

Here are some features you find in heavy duty circlip pliers and specialty types:

Durable high carbon steel construction

Bent handle style for improved grip and precision

Replaceable heads for different circlip sizes

Card spring range: 10-25mm

Size: 6 inches (150mm), Head size: 1.4mm

The table below shows the performance of heavy-duty circlip pliers in industrial settings:

Specification Category | Details |

|---|---|

Thrust Load Ring Pressure | Up to 4,000 kN |

Maximum RPM Limit | 84,000 RPM |

Max Load with Ring | 2,400 kN |

Materials Used | Carbon Steel, Stainless Steel, Beryllium Copper, Special Grades, Phosphor Bronze |

Finishes Available | Various plating and phosphate finishes |

Specialty circlip pliers include rack-type circlip pliers and angled tip circlip pliers. These tools help you handle unique applications, such as minimal clearance or inverted rings. You find these in a circlip plier set designed for advanced users.

Tool Types Available | Materials Used | Description |

|---|---|---|

Standard Pliers (Straight, 45°, 90°), Convertible Pliers, Heavy Duty Pliers | Carbon Steel, Stainless Steel, Beryllium Copper, Special Grades, Phosphor Bronze | External inverted metric retaining ring for minimal clearance |

Note: Heavy duty circlip pliers last longer and perform better under stress. They keep your workflow smooth in demanding environments.

Using the right types of circlip pliers for each job keeps your parts safe and your work efficient. Always match the circlip pliers types to your task for the best results.

You need to understand how circlip pliers work before you start any project. Circlip pliers come in two main types. Internal circlip pliers help you handle rings inside a bore. When you squeeze the handles, the tips move together. This action compresses the circlip, so you can fit it into a groove inside a hole. You often see this type in gearboxes or pumps.

External circlip pliers work differently. When you squeeze the handles, the tips move apart. This action expands the circlip, so you can slip it over a shaft. You will use external circlip pliers for axles or spindles. Both types of circlip pliers give you control and prevent damage to the ring or the part.

Tip: Always check which type you need before you start. Using the wrong tool can damage the circlip or the equipment.

Here is a quick comparison:

Feature | Internal Circlip Pliers | External Circlip Pliers |

|---|---|---|

Action | Compresses ring | Expands ring |

Use Location | Inside a bore | Around a shaft |

Handle Movement | Tips close together | Tips move apart |

Modern circlip pliers offer features that make your work easier. Many models have interchangeable tips. You can switch between straight, bent, or long-nose tips. This helps you reach circlips in tight or awkward spaces. Some circlip pliers have spring-loaded handles. This feature lets you open or close the pliers with less effort.

You may find adjustable circlip pliers in tool sets. These let you change the jaw width for different ring sizes. Some advanced models combine internal and external functions. You only need one tool for both jobs. This saves space and time.

If you want to know how to use circlip pliers, always match the tool to the job. Select the right tip and size. Hold the pliers steady and apply even pressure. This method keeps the circlip and the part safe.

Note: Special features improve safety and efficiency. They help you finish tasks faster and with fewer mistakes.

You often see circlip pliers in auto repair shops. Mechanics use them to install and remove snap rings on transmissions, wheel hubs, and brake systems. These rings hold gears, bearings, and shafts in place. You can use circlip pliers to reach tight spots under the hood. Many car parts need regular maintenance. You save time and avoid damage when you use the right tool.

Tip: Always check your car's manual before you use circlip pliers on any part.

Circlip pliers help you work on small devices. You use them to handle tiny snap rings inside motors, switches, and circuit boards. Electronics often have limited space. You need a tool that fits. Circlip pliers with fine tips let you work without damaging delicate parts. You can use them for both repairs and assembly.

Application Area | Why Use Circlip Pliers? |

|---|---|

Motors | Secure moving parts |

Switches | Hold components in position |

Circuit Boards | Remove/install snap rings |

You can use circlip pliers for many home projects. They help you fix faucets, appliances, and garden tools. Many household items have snap rings that hold parts together. You use circlip pliers to remove these rings without breaking them. Both DIY and professional use benefit from having a set in the toolbox.

Fix leaky faucets

Repair washing machines

Maintain power tools

Factories and workshops rely on circlip pliers every day. Workers use them to assemble heavy machinery, conveyor belts, and pumps. Industrial equipment often has large or tough snap rings. You need strong circlip pliers for these jobs. They help you keep machines running smoothly and safely.

Note: Always inspect your circlip pliers before you use them in industrial settings.

Choosing the right circlip pliers helps you work faster and safer. Start by looking at your task. If you need to remove or install a circlip inside a hole, pick internal circlip pliers. For rings around a shaft, use external circlip pliers. Next, check the size of the circlip. Circlip pliers come in different sizes, so match the tool to the ring. If you work on many projects, a circlip plier set gives you more options.

Tip style matters. Straight tips work best in open spaces. Bent or angled tips help you reach around corners or into tight spots. Long-nose tips reach deep inside assemblies. When buying circlip pliers, think about the jobs you do most often. A good circlip plier set covers many needs.

Tip: Always test the fit before you start. The right tool prevents damage and saves time.

Safety comes first when you use circlip pliers. Always wear safety glasses. Circlips can snap or fly off. Hold the tool firmly and keep your hands dry. Never force the pliers. If the circlip feels stuck, check the size and tip style. Use the right tool for each job. Store your circlip pliers in a safe place when not in use.

Safety Rule | Why It Matters |

|---|---|

Wear eye protection | Prevents injury from flying rings |

Use correct size | Avoids tool or part damage |

Keep hands dry | Improves grip and control |

Taking care of your circlip pliers keeps them working longer. Clean them after each use. Wipe off oil, dirt, or metal shavings. Lubricate the pivot points to keep movement smooth. Check for wear or damage. Replace worn tips or springs. Store your circlip plier set in a dry place to prevent rust.

You can follow these best practices for tool care:

Track how often you use each tool. This helps you spot problems early.

Set a regular cleaning and inspection schedule.

Train everyone who uses the tools on proper care.

Keep a record of repairs or replacements.

Review your maintenance plan often and make improvements.

These steps help you get the most from your circlip pliers and extend their lifespan.

You may face some common issues with circlip pliers. Tips can bend or break if you use too much force. Springs may wear out over time. Rust can form if you store tools in damp places. Sometimes, the pliers do not fit the circlip well. This usually means you need a different size or tip style. If you notice any problem, fix it before using the tool again.

Note: Regular checks and quick repairs keep your circlip pliers safe and reliable.

You now know how circlip pliers types affect your work. Choosing the right tool improves precision, safety, and speed. The table below highlights the main benefits:

Benefit | What You Gain |

|---|---|

Precision Handling | Accurate work in tight spaces |

Safety | Fewer injuries from flying parts |

Effectiveness | Faster, easier repairs |

Damage Prevention | Protects both circlips and equipment |

Review your toolbox. Replace worn or incorrect pliers. Follow safety steps and keep your tools clean. This guide helps you make smart choices for every project.

Internal circlip pliers compress circlips to fit inside a bore. External circlip pliers expand circlips to fit around a shaft. You need to choose the right type for your specific job.

No, you cannot. Circlip pliers come in different sizes and tip styles. You should match the pliers to the circlip size for safe and effective work.

You should clean your pliers after each use. Wipe off dirt and oil. Lubricate the pivot points. Store them in a dry place. Regular care keeps your tools working well.

Adjustable circlip pliers offer flexibility. Fixed pliers usually provide more strength and stability. For heavy-duty tasks, you should use fixed pliers.

You should always wear safety glasses. Circlips can snap or fly off. Gloves can help protect your hands. Safety gear keeps you safe during repairs.

Home | Products | About KENDO | Distribution Network | Events | Contact Us