- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

You need the right hand saw for every woodworking project. Crosscut saws, rip saws, backsaws, coping saws, and panel saws help you handle wood with accuracy and speed. Many beginners make mistakes when choosing a saw.

Some pick blades that are too long or too short for their workspace.

Others ignore the teeth per inch, which affects the smoothness and speed of each cut.

Handle comfort matters, so look for ergonomic grips that help you work longer and safer.

Choose the right hand saw for your project. Each type, like crosscut or rip saws, serves a specific purpose.

Look for ergonomic handles on saws. Comfort helps you work longer and with better control.

Understand TPI (teeth per inch). Higher TPI gives smoother cuts, while lower TPI is better for faster cutting.

Keep your hand saws clean and rust-free. Regular maintenance ensures better performance and longevity.

Start with essential saws like a crosscut saw and a rip saw. These tools cover most basic woodworking tasks.

You need hand saws for woodworking because they give you control and accuracy. When you use a hand saw, you can make precise cuts that power saws sometimes miss. Hand saws for woodworking help you work safely and quietly. You can use them anywhere, even if you do not have electricity.

Hand saws are quieter than power saws. You can focus better without loud noises. They are safer for beginners because they have fewer moving parts. You can control a handsaw more easily, which helps you make clean, straight cuts.

Here is a table that shows why many woodworkers choose hand saws over power saws:

Benefit | Description |

|---|---|

Precision and Control | Hand tools offer unmatched precision, making them ideal for intricate work. |

Portability | Hand tools can be used anywhere, perfect for remote job sites. |

Safety | Hand tools are often safer, especially for beginners, due to fewer moving parts. |

You can see that hand saws for woodworking are important for safety, control, and flexibility. These woodworking tools help you learn new skills and build confidence.

You should know the main types of hand saws for woodworking. Each saw has a special job. If you want to build furniture, make crafts, or repair wood, you need the right tools.

Here are the top five essential hand saws recommended by professional woodworkers:

Japanese Ryoba

This woodworking saw has two sides. One side cuts across the wood grain, and the other side rips along the grain. You can use it for many tasks.

Crosscut Panel Saw

You use a crosscut saw to cut across the grain. It makes clean, straight cuts. This saw is great for general woodworking.

Rip Saw

You use a rip saw to cut along the grain. It helps you split boards and make long cuts.

Dozuki Dovetail Saw

This back saw is perfect for fine joinery. You can make precise cuts for dovetails and other joints.

Coping Saw

You use a coping saw for curves and shapes. It helps you cut out patterns and details.

You also need a panel saw for cutting large sheets of wood. Each handsaw has a purpose. You should choose the right saw for your project.

Tip: Start with a crosscut saw and a rip saw. These two tools cover most basic woodworking tasks.

If you want a versatile option, try the Kendo Sharp Woodworking Hand Saw For Fast Cutting. This hand saw has triple-edge ground teeth for fast, smooth cuts. The ergonomic handle gives you comfort and control. The 65Mn blade stays sharp and works on many types of wood. You can choose from several sizes, so you always have the right tool for the job. The 7 TPI design balances speed and accuracy. This handsaw fits well in any woodworking toolkit.

When you pick your woodworking tools, look for quality and comfort. The right hand saw helps you work faster and safer. You can build, repair, and create with confidence.

You will find many types of hand saws in woodworking. Each handsaw has a special job. Knowing the types of hand saws helps you choose the right woodworking saw for your project.

A crosscut saw is one of the most common types of hand saws. You use it to cut across the grain of wood.

The crosscut saw has more, smaller teeth.

It features a less aggressive rake angle.

This design gives you a slower cut but makes the crosscut cleaner.

You get smooth, neat cuts when you use a crosscut saw for crosscutting boards.

The rip cut saw is another important type. You use a rip cut saw to cut along the grain. The teeth are larger and fewer than those on a crosscut saw. This makes the rip cut saw more efficient for ripping boards. Here is a table to compare the tooth design and efficiency:

Type of Saw | Tooth Design | Cutting Direction | Cutting Efficiency |

|---|---|---|---|

Rip Hand Saw | Fewer, larger teeth | Along the grain | More efficient for ripping |

Crosscut Saw | More, smaller teeth | Across the grain | More efficient for crosscutting |

You often use a rip cut saw for cutting wood to size and making long, straight cuts.

The back saw and dovetail saw are types of handsaws for joinery. You use a dovetail saw for making precise, shallow cuts in end-grain. This is important for dovetail joints. The carcase saw, another type, helps with almost all crosscuts in furniture making.

A panel saw is great for cutting large sheets of wood. It gives you straight, accurate cuts. The panel saw is also space-efficient and safer for big panels because the wood stays supported.

Advantage | Description |

|---|---|

Precision | Designed for accuracy, ensuring every cut is straight and to the exact measurement. |

Space Efficiency | Especially with vertical designs, the footprint is relatively small. |

Safety | Safer than using other saws for large panels as the material is well-supported throughout the cut. |

You use a coping saw for curves and detailed shapes.

The thin, flexible blade lets you make intricate cuts.

The C-shaped frame gives you better control.

You can cut on the pull stroke for more accuracy.

The coping saw handles thicker materials than a fret saw.

A keyhole saw is a special type for small, tight spaces. You use it for sawing mortises in woodworking. This handsaw helps you make holes or cutouts inside wood panels.

The Japanese pull saw is different from Western types of hand saws. You cut on the pull stroke, not the push. This makes it easier to control and less tiring. The blade is thinner, so you get cleaner cuts and less binding. Here is a table to show the differences:

Feature | Japanese Pull Saw | Western Hand Saw |

|---|---|---|

Cutting Technique | Cuts on the pull stroke | Cuts on the push stroke |

Precision | Easier to achieve due to less binding | Can be less precise due to push technique |

Kerf | Thinner blades for cleaner cuts | Thicker blades for rough cuts |

User Fatigue | Less tiring on arms | More tiring due to push technique |

Ideal Use | Precise joinery | Rough lumber cutting |

Some types of hand saws have special uses. You use a bow saw or veneer saw for dovetailing, crosscutting, joinery, mortise-and-tenon work, cutting corner blocks, and cutting dowel rods. These types help you with detailed or unique woodworking tasks.

Many woodworking projects need you to cut across the wood grain. This helps you shape boards and trim the ends. You can also make slopes this way. A crosscut saw is the tool for these jobs. Cutting across the grain removes wood fast and gives you more control. You need sharp tools for end grain. Slicing off wood makes your cuts look clean.

Here are some woodworking jobs that need you to cut across the grain:

Trim boards to the right length

Make sloped edges

Shape end grain for joinery

Remove extra wood when carving

To cut better, try these handsaw tips:

Start your cut straight by using the saw’s reflection to line up with the board.

Use crosscut teeth first, then switch to rip teeth if you need.

Begin at the corner near your line and make a small groove before cutting on the line.

Hold the handsaw loosely so the teeth do the work.

Use depth stops on Japanese saws to get even results.

Tip: Practice these steps to get better at crosscutting. Your woodworking projects will look more professional.

Ripping means cutting wood along the grain. You use a rip saw for this. Ripping is good for making boards smaller and for long, straight cuts. Mark your cut line carefully before you start. Begin at the corner of your line and use your thumb to guide the blade. This helps you control the saw and keep the cut straight.

Here are some best ways to rip wood:

Pick the right saw: crosscut saw for crosscuts, rip saw for ripping.

Draw your line clearly before you begin.

Use your thumb to steady the blade at the start.

You use ripping for many projects, like making table legs, cutting wood for frames, and making boards fit cabinets.

You need careful cuts for joinery in fine woodworking. Dovetail saws help you make dovetail joints. Backsaws are good for many joinery jobs. Japanese saws cut on the pull stroke, which gives you speed and accuracy. Coping saws are great for curves and for taking out extra wood in joinery. You use these saws when power tools are too rough for the job.

Note: The right woodworking saw for joinery gives you strong, neat joints. It also makes your woodworking projects better.

A coping saw is used to cut curves and tricky shapes in wood. The thin blade lets you follow patterns and make detailed designs. This is helpful for making fancy edges, cutting out shapes, and working on custom projects. Coping saws help you do things that are hard with other tools.

Fine detailing needs control and accuracy. You use small handsaws like dovetail saws and coping saws for these jobs. These saws help you add fancy touches, shape joints, and finish edges. Fine detailing makes your woodworking projects special and shows your skill.

Uses for Handsaws in Woodworking Projects | Example Tasks |

|---|---|

Cutting across wood grain | Trimming boards, shaping ends |

Ripping wood | Resizing boards, making frames |

Precision and joinery cuts | Dovetail joints, tenons |

Curves and intricate shapes | Decorative edges, patterns |

Fine detailing | Shaping joints, finishing |

The good things about handsaws are control, accuracy, and being able to work on many woodworking projects without power tools.

When you choose a handsaw, you need to look at the TPI, or teeth per inch. TPI tells you how many teeth sit on one inch of the blade. A higher TPI gives you smoother cuts. A lower TPI helps you cut faster but leaves rougher edges. For woodworking, you want to match the TPI to your project. If you work with thick wood, pick a saw with fewer teeth. For fine work, use a saw with more teeth. The Kendo Sharp Woodworking Hand Saw For Fast Cutting uses a 7 TPI blade, which balances speed and control for many tasks.

Tip: Always check the TPI before you start cutting. The right TPI makes your job easier and your cuts cleaner.

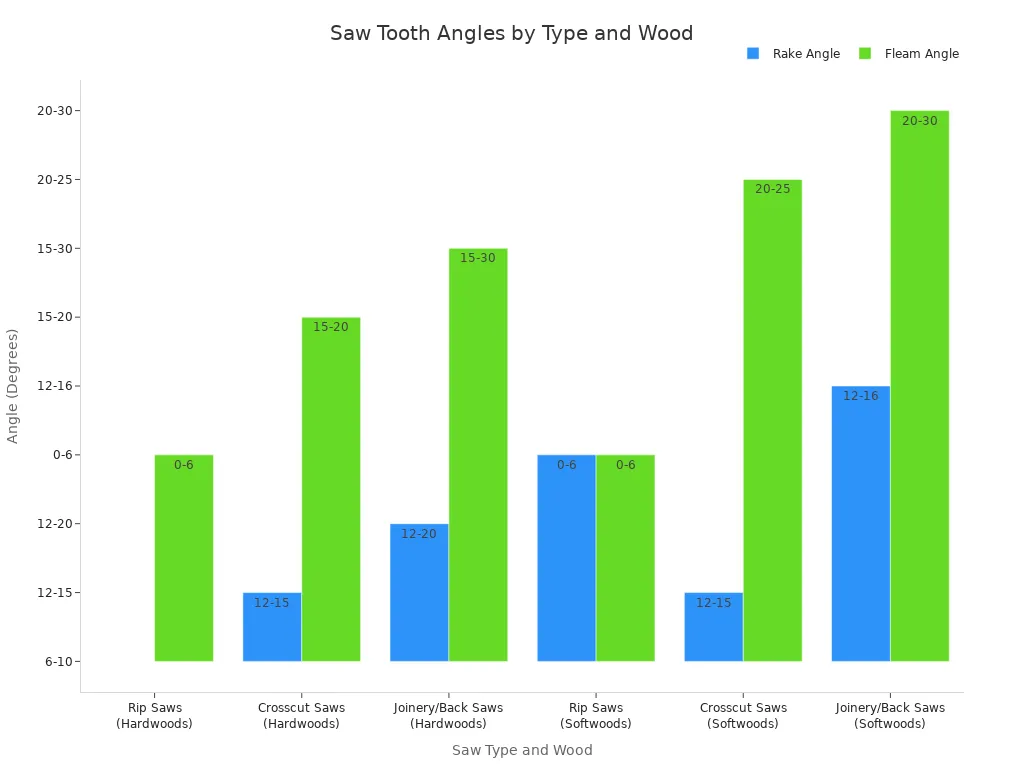

The tooth set and shape decide how your handsaw moves through wood. Tooth set means how the teeth bend away from the blade. This helps the saw clear sawdust and keeps the blade from sticking. Tooth shape includes rake and fleam angles. These angles change how the saw cuts. Rip saws have a small rake angle for straight cuts. Crosscut saws use a bigger fleam angle for slicing across the grain.

Type of Saw | Rake Angle (Degrees) | Fleam Angle (Degrees) |

|---|---|---|

Rip Saws (Hardwoods) | 6-10 | 0-6 |

Crosscut Saws (Hardwoods) | 12-15 | 15-20 |

Joinery/Back Saws (Hardwoods) | 12-20 | 15-30 |

Rip Saws (Softwoods) | 0-6 | 0-6 |

Crosscut Saws (Softwoods) | 12-15 | 20-25 |

Joinery/Back Saws (Softwoods) | 12-16 | 20-30 |

Blade material affects the durability of your hand saw. Tungsten carbide tipped blades last a long time and stay sharp. Polycrystalline diamond blades offer exceptional durability and resist wear, making them great for tough jobs. Blade length changes how you use the saw. Short blades help you make precise cuts. Long blades work better for big pieces of wood. You need to pick the right blade for your woodworking saw to get the best results.

Blade Material | Description |

|---|---|

Tungsten Carbide Tipped (TCT) | Known for long lifespan and sharpness retention, suitable for various wood types and general woodworking applications. |

Polycrystalline Diamond (PCD) | Exceptional durability and wear resistance, ideal for cutting abrasive materials and delivering clean cuts. |

Handle design matters for comfort and control. You want a handle that fits your hand and lets you work for hours without pain. Some handles have a special curve to match your grip. Others include a bigger finger rest for better support. An optimized handle gives you more control and helps you guide the saw during cutting. The Kendo hand saw features an ergonomic handle with a non-slip grip, so you can use your tools longer and safer.

The handle features a newly redesigned curvature.

It includes an enlarged finger rest.

The optimized hand capacity enhances comfort and control during use.

A good handle lets you focus on your project, not on hand fatigue. Choose tools with handles that feel right for you.

You want your handsaw to last for years. Cleaning and rust prevention keep your woodworking saw in top shape. After each use, wipe the blade with a dry cloth to remove sawdust and moisture. For stubborn spots, polish the blade with steel wool or a scotch brite pad. Then, use an oily rag to wipe the blade. This step helps stop rust from forming.

To protect your hand saw, try these methods:

Apply camellia oil to the blade. This oil is non-toxic and safe for wood.

Use Johnson's Paste wax or beeswax as a barrier against moisture.

Try Boeshield for a slick, protective finish.

Store your tools in a heated space to reduce condensation.

In humid areas, add a wax film to the blade for extra protection.

Tip: A clean, rust-free handsaw makes cutting smoother and safer.

A sharp blade gives you better control and cleaner cuts. You can sharpen your handsaw at home with a few simple tools. Follow these steps for best results:

Clamp the handsaw securely in a vice. This keeps it steady while you work.

Use a saw set tool to align the teeth. This step ensures the kerf, or cut width, stays even.

File the teeth so they are all the same height. This process is called jointing.

Sharpening your blade often means you spend less time struggling with tough wood. You also get more accurate cutting every time.

Proper storage protects your hand saws from damage. Hang your saws on a wall rack or store them in a dry toolbox. Heated toolboxes help prevent moisture buildup. Always keep your handsaw away from damp places. If you store your saw with other tools, use a blade guard to prevent nicks and scratches.

Storage Method | Benefit |

|---|---|

Wall rack | Keeps saws organized |

Heated toolbox | Reduces condensation |

Blade guard | Prevents blade damage |

Remember: Good storage habits keep your woodworking saw ready for your next cutting project.

You need to match your handsaw to your woodworking project. Each project has different needs. If you work on large boards, pick a longer blade for bigger cuts. For small crafts or fine joinery, choose a shorter blade for more control. The type of cut matters too. Use a crosscut saw for cutting across the grain. Use a rip saw for cutting along the grain. Always think about what hand saws do you need before you start.

Tip: Write down your project steps. This helps you decide which woodworking saw fits each task.

Wood type changes how your handsaw works. Hardwoods like oak or maple need a strong blade and sharp teeth. Softwoods like pine cut easier, but you still need the right tooth design. Thick wood needs a saw with fewer teeth per inch (TPI) for faster cutting. Thin wood benefits from a higher TPI for smoother edges. Always check the wood before you pick your hand saw.

Wood Type | Best Saw Choice | TPI Recommendation |

|---|---|---|

Hardwood | Durable blade, sharp teeth | 7-10 |

Softwood | Flexible blade, fine teeth | 10-14 |

Comfort matters when you use a handsaw for long periods. Look for an ergonomic handle that fits your grip. A soft, non-slip handle reduces fatigue and gives you better control. If you are new to woodworking, start with a saw that feels light and easy to guide. The Kendo Sharp Woodworking Hand Saw has an ergonomic handle and a balanced 7 TPI blade. This design helps you cut wood with less effort and more accuracy.

Note: Test the handle before you buy. Your hands should feel relaxed, not strained.

You want a handsaw that lasts. Quality tools save you money over time. Check the blade material for durability. Hardened steel blades stay sharp longer and resist wear. Look for a saw with a strong, comfortable handle. Compare prices, but do not choose only by cost. A reliable hand saw makes cutting safer and easier. The Kendo saw offers quality features at a fair price, making it a smart choice for many woodworking projects.

Feature | Why It Matters |

|---|---|

Blade Material | Affects durability |

Handle Comfort | Reduces fatigue |

TPI | Matches cutting needs |

Price | Balances value and quality |

Choose your woodworking saw with care. The right handsaw helps you finish your project with confidence.

You need the right hand saw for woodworking success. When you understand the types and uses of hand saws, you make better choices for every wood project. Start with the essential hand saws and look for quality options like the Kendo Sharp Woodworking Hand Saw For Fast Cutting. You can build skills and tackle your next woodworking project with confidence.

You should start with a crosscut saw. This saw helps you make straight cuts and learn basic woodworking skills. Look for a comfortable handle and a blade with 7 to 10 TPI.

You need to clean your saw after each use. Use a file to sharpen the teeth when they get dull. Store your saw in a dry place to prevent rust.

You can use a versatile saw like the Kendo Sharp Woodworking Hand Saw for many wood types. For best results, match the saw’s TPI and blade material to your project.

Your saw may get stuck if the blade is dull or the teeth are not set correctly. Clean the blade and check the tooth set. Use a saw with the right TPI for your wood.

You should pick a saw size based on your project. Use a longer blade for big boards and a shorter blade for small crafts. Check the blade length before you buy.

Home | Products | About KENDO | Distribution Network | Events | Contact Us